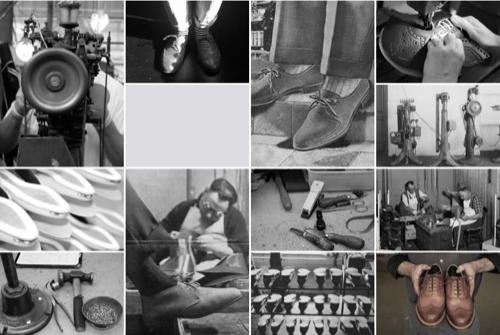

Established back in 1866, Grenson is one England’s most premier shoemakers. Seldom do we see a brand of such stature let loose and really give its customers an idea of what goes into making their product. If you get a chance, head to Grenson’s website for their How We Make Our Shoes segment which outlines the brand’s shoemaking process from beginning to end along with some historical tidbits.

All Grenson shoes are “Goodyear Welted”, a process invented in the 1800’s in England that is a time consuming way of making shoes, but means that the product lasts longer than any other type of shoes. It also means that the shoe can re-soled many times over making them a wonderful investment.

There are 4 main departments connected with manufacturing within a footwear company and the components follow a progressive route through each of these departments to produce the finished shoes. The departments are, Clicking, Closing, Lasting/ Making, Finishing/ Shoe Room. From start to finsh will take around 3 weeks to make a top quality Goodyear welted shoe whereas in cheaper shoe production the rule of thumb is often that if it cant be made in 5 minutes it wont be profitable!

Head to Grenson for the full feature.

![Journal de Nimes Nº5 - The British issue [July 2010]](https://porhomme.com/wp-content/uploads/2010/07/tenue-journal-de-nimes-nº5-the-british-issue-july-2010-1.jpg)